The KFI™ process pumps series by EMM™ has been specially designed for use in the chemical industry and sewage treatment plants.

The KFI™ process pumps series by EMM™ has been specially designed for use in the chemical industry and sewage treatment plants.

The KFI™ pumps by EMM™ are centrifugal, rotary, single-stage, horizontal pumps with a spiral intake channel and integrated base with bearing assembly.

The pumps are comprised of two main units, i.e. the bearing assembly with high capacity bearings applied and the flow system. The immobile parts of these two units are connected with a fastening and centralising ring, while the centrifugal elements are set on a shared shaft. The suction flange is set horizontally to the shaft position, while the discharge flange is set vertically with the pump axis.

The shaft can be sealed in one of the following four ways:

- gland with full sealing liquid flow

- gland with limited sealing liquid flow

- FDS® dynamic sealing system

- mechanical sealing

The flow system elements are made with highly alloyed chromium cast iron characterised by a high hardness (approx. 63-65 HRc), with very good abrasion and corrosion resistance. However, due to the main application of KFI™ type pumps in ths chemical industry, the pumps are also produced in versions with austenitic alloys (acid-proof), suitable for pumped slurry.

The design of the pumps enables adjustment of the clearance between the impeller and casing.

The bearing system does not require additional cooling – the bearings are lubricated with oil.

Technical data:

Flowrates: up to 1000 cu.m./hr.

Heads up: to 130 m

The MFI series of types is specially designed to pump sewage, slurry and post-production waste stored in settling tanks located below the floor level.

The MFI series of types is specially designed to pump sewage, slurry and post-production waste stored in settling tanks located below the floor level.

The MFI pumps by EMM™ are vertical, centrifugal, rotary, single-step pumps with open or closed impeller. What is particularly typical of the MFI pumps is the lack of bearing mounting in the submerged part. The centrifugal elements of the pump are set on a rigid shaft supported by bearings in the part that has no contact with the pumped medium.

The elements of the flow system are usually made of highly alloyed chromium cast iron (white cast iron) characterised by high hardness (approx. 63-65 HRc), very good abrasion and corrosion resistance, however because of a wide range of possible applications, pumps are manufactured in various material versions, depending on application requirements. For production we mainly use cast iron, carbon steel as well as austenitic alloys – acidproof.

The pumps’ design enables the adjustment of clearance between the impeller’s front and the body.

The bearing system does not require additional cooling, as the bearings are smeared with grease.

Technical data:

Flowrates up: to 265 cu.m./hr.

Heads up: to 46 m

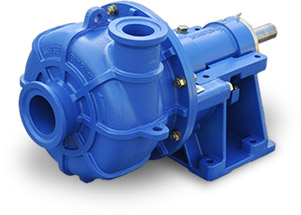

EFI-HP™ series of types is specially designed to be used in filter-press supply. However, due to the considerable lifting height, such pumps are also well-suited to other applications.

EFI-HP™ series of types is specially designed to be used in filter-press supply. However, due to the considerable lifting height, such pumps are also well-suited to other applications.

The EFI-HP™ pumps by EMM™ are centrifugal, rotary, single-step, horizontal pumps with a spiral intake channel and separate bearing system.

Similarly to the EFI™ pumps, these pumps are comprised of two main units, that is the bearing system where bearings with very high capacity are used and which is fastened to the base, and the flow system, the so-called wet component. The immobile parts of those two systems are connected with a fastening and centralising ring, while the centrifugal elements are set on a shared shaft. The suction flange is situated horizontally in the shaft axis, and the discharge flange can be set in one of eight positions, depending on one’s needs. The pump’s body is protected from the inside with replaceable protective lining.

The shaft can be sealed in the four following ways:

- Gland with full sealing liquid flow

- Gland with limited sealing liquid flow

- FDS® dynamic sealing system

- Mechanical sealing – front

The elements of the flow system are usually made of highly alloyed chromium cast iron (white cast iron) characterised by high hardness (approx. 63-65 HRc), very good abrasion and corrosion resistance, however because of a wide range of possible applications, pumps are manufactured in various material versions, depending on application requirements. For production we mainly use cast iron, carbon steel as well as austenitic alloys – acidproof.

The pumps’ design enables the adjustment of clearance between the rotor’s front and the body.

The bearing system does not require additional cooling, as the bearings are smeared with grease or oil.

Technical data:

Flowrates up: to 520 cu.m./hr.

Heads up: to 100 m

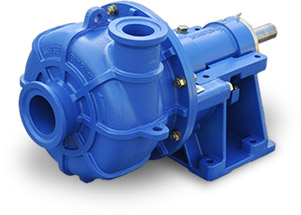

The EFI™ pumps by EMM™ are centrifugal, rotary, single-stage, horizontal pumps with a spiral intake channel and separate bearing system.

The EFI™ pumps by EMM™ are centrifugal, rotary, single-stage, horizontal pumps with a spiral intake channel and separate bearing system.

The pumps are comprised of two main units, that is the bearing system with high capacity bearings applied attached to the base, and the flow system, the so-called wet component. The immobile parts of those two systems are connected with a fastening and centralising ring, while the centrifugal elements are set on a shared shaft.

The shaft can be sealed in the four following ways:

- Gland with full sealing liquid flow

- Gland with limited sealing liquid flow

- FDS® dynamic sealing system

- Mechanical sealing – front

The elements of the flow system are usually made of highly alloyed chromium cast iron (white cast iron) characterised by high hardness (approx. 63-65 HRc), very good abrasion and corrosion resistance, however because of a wide range of possible applications, pumps are manufactured in various material versions, depending on application requirements. For production we mainly use cast iron, carbon steel as well as austenitic alloys – acidproof.

The pumps’ design enables the adjustment of the clearance between the rotor’s front and the body.

The bearing system does not require additional cooling, as the bearings are smeared with grease or oil.

Technical data:

Flowrates up: to 1800 cu.m./hr.

Heads up: to 75 m

The KFI™ process pumps series by EMM™ has been specially designed for use in the chemical industry and sewage treatment plants.

The KFI™ process pumps series by EMM™ has been specially designed for use in the chemical industry and sewage treatment plants.

EFI-HP™ series of types is specially designed to be used in filter-press supply. However, due to the considerable lifting height, such pumps are also well-suited to other applications.

EFI-HP™ series of types is specially designed to be used in filter-press supply. However, due to the considerable lifting height, such pumps are also well-suited to other applications. The EFI™ pumps by EMM™ are centrifugal, rotary, single-stage, horizontal pumps with a spiral intake channel and separate bearing system.

The EFI™ pumps by EMM™ are centrifugal, rotary, single-stage, horizontal pumps with a spiral intake channel and separate bearing system.